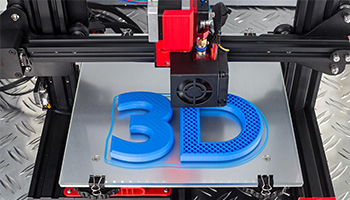

The term ‘3D printing’ has caught the eye of the world ever since the concept came into existence and successfully got implemented. Not too long ago, the very idea of creating 3D objects using machines by adding layers of material on top of one another seemed absurd. Many of you might even still think it as a type of printing by putting ink on a piece of paper. Contrary to that, 3D printing (additive manufacturing) is an emerging technology that enables us to create objects by adding material to layer by layer rather than using ink.

Today, 3D printers have occupied our home, workspace and classrooms. With this revolutionary technology, creating products for the medical, aerospace, dental and automotive industries has now become easy. Moreover, 3D printing is taking over into other spaces of our lives including toy and furniture manufacturing, art and fashion. If you aren’t familiar with this technology, here’s everything you should know about 3D printing that is taking the manufacturing world by storm.

What Is 3D Printing?

Before diving deep into 3D printing technology, it’s imperative to know what exactly a 3D printer is. Does it work like any other printer? If not, what makes it so special? 3D printers are a new generation of machines that are capable of making pretty much anything from ceramic cups to machine parts, stoneware vases, chocolate fondue and even human heart. 3D printers are nothing like your ordinary printers, they are special in the sense that they can produce all types of objects in different materials, all from the same machine. Sounds wonderful right? It is.

Now the question arises is what kind of material does a 3D printer use? 3D printers use ABS (acrylonitrile butadiene styrene) thermoplastic to create 3D objects. Thermoplastics are a type of plastics that melt when you head them and turn solid as soon as you cool them. In fact, thermoplastics are used in a wide range of objects including LEGO bricks, refrigerator parts, and plastic parts of a computer to name a few.

Since you are now aware of the material used by 3D printers, let’s come to the point and understand what 3D printing really is. 3D printing is a technology of producing/manufacturing 3D objects by adding material a layer at a time. Here, no special tools are needed as parts can be manufactured directly onto the platform layer-by-layer.

Examples of 3D Printing

Let’s take a look at the applications of 3D printing technology. The technology can be used for creating:

- Dental products

- Furniture and Décor items

- Fossils reconstruction

- Bones and body parts reconstruction

- Automobile parts

- Eyewear

- Prosthetics

- Movable houses etc

How Does 3D Printing Work?

Think of the whole 3d printing mechanism like making a loaf of sliced bread, only in reverse where you bake each slice and then glue them together into a whole loaf. That’s how a 3D printer prints objects. Sound pretty simple right? Well, this simple-appearing technique took decades to implement and raise questions every now and then.

In this technique, a 3D printer basically prints one layer of material, wait for it to dry and then print the next layer on top of the dried layer. Since layering is a complex task, it is important to have a quality 3D printer otherwise your object will appear like junk. The quality of the object you get as an outcome depends on the quality of the printer. With this technology, you can even print bike and car parts without using any tools by leaving gaps in the right places.

Advantages of 3D Printing Technology

3D printing technology opens up the possibility of a sustainable future where you can make everyday items to your requirements without wasting time and money as it generally happens in the case of traditional manufacturing. Here’s what our future with 3d printing beholds-

- Affordable technology made available to the masses.

- 10X times faster speed

- Low start-up cost

- Creating models and rapid prototypes in fewer hours/days

- Achieving geometric complexity at no extra cost

- Easy personalization of each and every part

- Large range of specialty materials and so on.